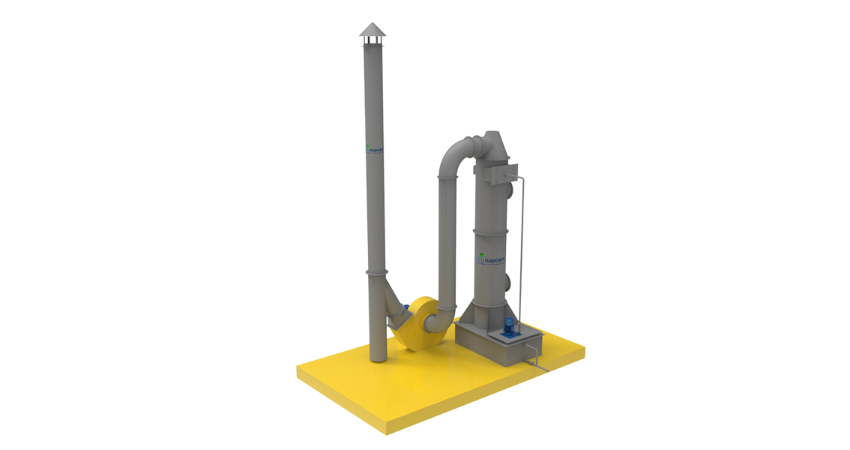

Here are the key components and working principles of a Packed Bed Scrubber

-

Packing Material

The heart of a packed bed scrubber is the packing material. It is typically a bed of various materials, such as plastic or metal structured packing, random packing, or special materials designed to maximize the contact between the contaminated gas stream and a scrubbing solution.

- Scrubbing Solution

- Gas Inlet

- Counter flow or Cross flow

- Mass Transfer

- Mist Elimination

- Outlet

- Overflow and Re-circulation